SAE Felt: What is it and how is it made?

What is SAE Industrial Felt?

SAE industrial felt, or technical felt, is nonwoven wool felt used in technical applications. There are two methods of manufacturing industrial felt: wet felting or dry needle punch felting.

Technical felts are produced in a variety of thicknesses, densities, and compositions to meet a wide range of needs. The SAE, formerly known as the Society of Automotive Engineers, mandates the standards of measurements applied to nonwoven wool felts used in:

- Gaskets

- Dryer seals

- Pads

- Washers

- Vibration Cushioning

- Dust Shields

- Acoustic Panels

At Bouckaert, we custom manufacture our SAE industrial felt using the needle punch method. Before discussing the differences between manufacturing methods, here are the characteristics of SAE felts and nonwoven wool felts in general.

Characteristics of Industrial Wool Felt

Felt is a versatile fabric explicitly engineered for high-pressure applications in specialized industries. With the natural benefits of using wool fiber (click here for our previous post on wool felt usages), here are some of the advantages to using industrial wool felt:

- Maintains its physical properties as it wears

- Highly absorbent and moisture-wicking (will seal out lubricants and oil)

- Sound and vibration dampening

- Does not ravel or fray

- Resistant to wear and tear

- Acts as a filtration system (gas and oil applications)

- Excellent padding for moving parts in machinery

- Natural fire-retardant properties

Industrial applications such as these require high levels of aversion to abrasion, oil and grease absorption, and wear and tear. To ensure the best application results, SAE felts are classified by their density, wool content, and durability.

- Density: Each grade of SAE felt ranges from hardest to most pliable, the main differing characteristic between felt grades. The thickness of pressed wool felt is controlled by the amount of pressure or needling applied during the manufacturing process. The denser the felt, the better it will retain its shape against the physical environment.

- Wool content: Each grade of SAE felt is (usually) a combination of raw wool fibers and polyester fiber but additional materials such as cotton, rayon/viscose, synthetic, or plant fibers can be used instead. These “filler” materials are added to create a particular characteristic to the final product that can not be achieved by wool and/or polyester alone.

- Durability: During the manufacturing process, the more pressure/needling applied (we will get into this in the next segment), the denser the felt will be. Durability relies, in part, on the amount of densification.

To note, the color of SAE industrial felts will vary. Since the wool used is natural and undyed, there is no way to control color consistency from lot to lot. There are also strict tolerance requirements based on wool content and density combined. The shape of wool can change naturally (depending on temperature) or manually (from cutting the material); density and wool content need to be adjusted to consider tolerance issues.

The Differences in Manufacturing

Wet Felting VS Dry Needle Punch Felting

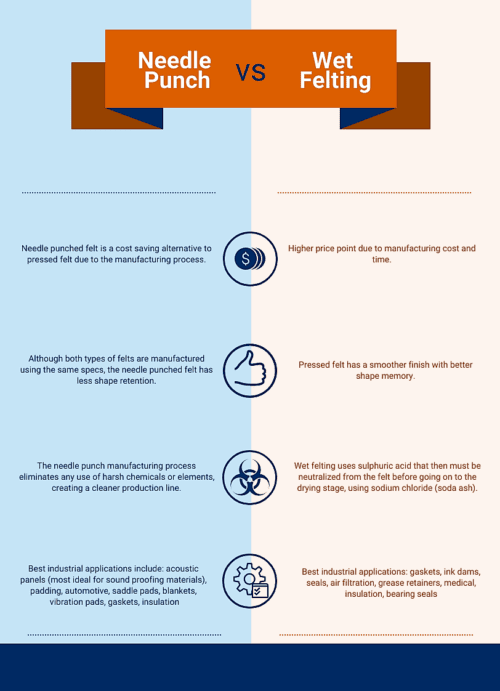

All technical felts are produced under the same specs; the difference lies in the manufacturing process. Despite these “technical” differences, both processes in making SAE grade felt start the same way.

The wool fiber is first cleaned and blended with any additional synthetic materials before the carding process. The carding machine disentangles and mixes the fibers together to create a uniform web, aligning the individual fibers into a singular direction. Several of these webs are layered in alternating directions on a machine called a cross-lapper to build-up to the weight of the desired finished felt. This layered material will be much thicker (and less dense) than the finished product as it has not been densified yet. This material is referred to as a batt.

Wet Felting

The wet felting manufacturing process is known as the more “traditional” way of producing nonwoven felts. It uses heat, moisture, and pressure to mat and densify the fiber together.

The batts are wetted with hot water and fed into a plate hardener. The plate hardener applies vibrational pressure to the wetted material using rollers to help the fibers interlock together. The hot water, added acid, and pressure eventually cause the batts to shrink down in size, creating the densely matted fibers of a pressed felt.

The wet felt is left with a sulfuric acid residue that is then neutralized in tanks filled with sodium chloride (soda ash) and warm water solution. Once the felt is neutralized, it goes through a refulling machine to smooth out any irregularities on the surface. The felt must then be dried either in a dryer or oven or hung and stretched in a drying room.

Needle Punch Method (Dry Needle Felting)

Here at BIT, we manufacture our SAE grade felts using the needle punch method. Needle punched SAE felt is marked with an “N” for “needled in the official designation (example F-7N). Here’s the difference in manufacturing:

As the name suggests, dry needle punch felting eliminates the use of moisture. Instead, the batts enter a needle loom; a precise machine that uses thousands of barbed needles mounted on a needle board to pierce the layered webs of fiber. The repeated punching of the needles entangles the fibers together to create the thick, dense felt.

Depending on the desired density, some needle punched SAE felts will then go through a heated press to further densify the material. Read more in-depth on the needle punch method here.

So Why Use Needle Punched Felt Vs A Pressed Felt for your SAE Needs?

The Pros and Cons of Needle Punched SAE Felt Vs Pressed SAE Felt

The use of chemicals in wet pressed felts gives the advantage of creating a smoother finish that allows the material to hold its shape better as it wears. The upside for needle punched felt is its economical and eco-friendly benefits; eliminating the use of harsh elements makes a cleaner production line that is more cost and time effective.

For exceptional sound insulation, needle punched felt is the go-to choice for acoustic paneling needs. But if there is one thing to remember when choosing between a wet felt or a needle punch felt, it is that both are produced under the same specs mandated by the SAE. The performance of needle punch felt is not compromised because of its manufacturing process.

Want to know how BIT can add value to your business by providing custom manufactured SAE grade industrial felts? Get in touch today!

1 Comment

Nicola Wylie

Hi, I am wanting to produce a range of fashion bags with felt, wondering which method of felting would be a better fit? Will either be ok?

Regards Nicola