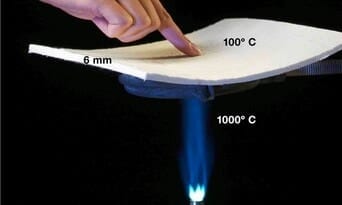

When your company’s equipment handles demanding high temperatures, you require more than just adequate thermal insulation. Bouckaert Industrial Textiles supplies top-quality nonwoven high-temperature thermal insulation materials for temperatures ranging from -300F to 2000F made from polyesters, aramids, fiberglass, Panox, viscose rayon, and other specialty materials.

You can maintain firm control of your supply chain and quality standards when you use Bouckaert’s high-performance thermal insulation materials and services. Our services focus on supplying thermal insulation materials for industries ranging from automotive manufacturing to oil and gas pipeline insulation. Created to stand-alone or as part of a composite, our products can withstand both extreme low and high-temperature environments as well as critical failure scenarios when lives hang in the balance.

Benefits of Nonwovens in High-Temperature Thermal Insulation

Whether your insulation need is for wrapping an HVAC system or as part of a composite on the space shuttle re-entry system, nonwovens have long played an important role in the field. These days, there are numerous options for thermal management but nonwovens still hold pride of place due to their capabilities and a multitude of benefits for use as a stand-alone insulator or as part of a composite, including:

- Low thermal conductivity capability

- Strength + flexibility

- Lighter weight

- Moldable

- Extreme temperature capability

- Combinable into composite solutions

- Lower cost solution vs most foams

- Lower environmental and safety concerns vs rockwool

Product Lines

Temp-Sonic is a family of products from Bouckaert Industrial Textiles comprised of 100% fiberglass or fiberglass blended with polyester or polypropylene for use as acoustical and/or high-temperature thermal insulation.

Applications

Bouckaert Industrial Textiles’ thermal insulation products appear in a wide range of industrial applications, such as:

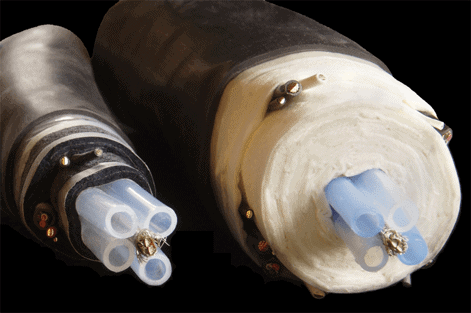

- Oil and gas pipelines

- High-temperature baghouses and filtration system

- Kilns

- HVAC Applications

- Engine-side Heatshields

- Furnaces

On top of this range of product offerings and industrial uses, we strive to deliver finished projects on time or even sooner. We offer expedited delivery through our Just in Time (JIT) Delivery system, and we can set up Kanban systems as needed for large-scale production. We can scale our production capacity from small runs and prototyping to mass production of nonwoven textile fabrics.

In addition to the SAE standards outlined above, all our products meet ASTM requirements and are UL Fireproof certified. Throughout our business, we strive to create a culture of highly innovative problem solving that, when combined with our excellent customer service wing, results in a consistent standard of quality for all our products.