High-Temperature Nonwoven Felts: Applications Across Industries

In today’s fast-evolving industrial landscape, high-temperature nonwoven felts applications are gaining recognition for their ability to handle the most challenging environments. Whether it’s in automotive, aerospace, or oil and gas, nonwoven felts provide thermal insulation, durability, and flexibility where other materials fall short. Industries that deal with extreme heat demand materials that offer excellent performance and reliability under stress. Nonwoven felts deliver exactly that, making them indispensable across various high-performance applications.

In this article, we explore how these materials are used, including their integration with cutting-edge technologies like aerogels and their essential role in sectors like oil and gas pipeline insulation.

1. High-Temperature Nonwoven Felts Applications in Automotive and Heavy-Duty Equipment

The automotive and heavy-duty equipment industries are synonymous with high temperatures, especially in components such as engines, exhaust systems, and catalytic converters. Nonwoven felts, particularly those made from fiberglass or fiberglass/polyester blends, have become critical in these sectors, offering superior thermal management and heat resistance.

Engine and Exhaust Insulation with Nonwoven Felts

Nonwoven felts provide insulation in heat shields, protecting key components from heat exposure and maintaining optimal engine performance. In combustion engines, keeping the temperature under control is critical for fuel efficiency and the longevity of components. By acting as an insulator in exhaust systems and catalytic converters, nonwoven felts help manage heat more effectively, reducing the risk of damage and improving overall emissions performance.

Heavy-Duty Equipment and High-Temperature Nonwoven Applications

Nonwoven felts are heavily used in the insulation of industrial machinery and heavy-duty trucks, where components are often subjected to extreme temperatures. These felts protect equipment from heat while contributing to longer operational lifespans and lower maintenance costs. The durability and heat-resistant properties of nonwoven felts make them an ideal choice for heavy-duty environments where reliability and performance are crucial.

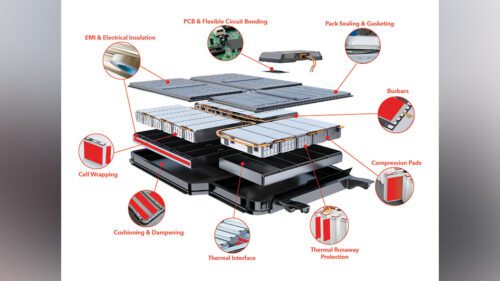

EV Battery Insulation with Nonwoven Felts

In the electric vehicle (EV) industry, managing heat generated by battery packs is crucial for performance and safety. Nonwoven felts are increasingly being used as thermal insulators in EV batteries. These felts help manage heat, reducing the risk of overheating without adding unnecessary weight. This insulation solution is essential for ensuring the longevity and safety of EV batteries as they generate significant heat during operation.

2. Applications of High-Temperature Nonwoven Felts in Mass Transit and Aerospace

When it comes to mass transit and aerospace, safety and efficiency are paramount. Both sectors involve systems that must function under high stress and extreme temperatures, whether it’s a subway train moving through tunnels or an aircraft soaring at high altitudes. In both cases, nonwoven felts provide the thermal insulation needed to keep these systems operational while maintaining safety standards.

Mass Transit Systems

In buses, trains, and other public transit vehicles, nonwoven felts are used to insulate sensitive electrical components and protect passengers from heat in areas such as the engine compartments and exhaust systems. As these vehicles strive for energy efficiency, the use of lightweight yet durable materials like nonwoven felts helps reduce overall weight without sacrificing safety.

Aerospace Applications

Nonwoven felts are commonly integrated into aerospace designs for use as heat shields, engine insulation, and thermal barriers. Their ability to perform at temperatures up to 2000°F ensures that they meet the stringent demands of modern aerospace engineering.

3. Nonwoven Felts as Carriers for Aerogels in High-Temperature Applications

One of the most innovative uses of nonwoven felts is as a substrate for aerogels. Aerogels, known for their extraordinary insulating properties, are among the lightest and most effective thermal insulators in the world. Combining them with nonwoven felts creates materials capable of withstanding even higher temperatures while maintaining flexibility and lightweight characteristics.

Aerogel-Enhanced Insulation

Nonwoven felts serve as a carrier for aerogels, enabling manufacturers to produce ultra-lightweight, high-performance insulation products. This combination is often used in industries requiring exceptional thermal control, such as oil and gas pipeline insulation.

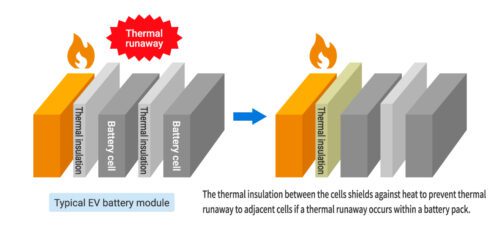

EV Battery Insulation with Aerogel

In the electric vehicle (EV) industry, managing thermal runaway in battery packs is critical for safety and performance. Nonwoven felts, when combined with aerogel, provide lightweight, highly effective insulation that helps mitigate the risk of thermal runaway by containing heat and preventing it from spreading across cells. This advanced insulation is particularly effective in EV battery systems, where safety and efficiency are paramount. For more information on thermal runaway mitigation strategies in EV batteries, visit Charged EVs.

4. Applications of High-Temperature Nonwoven Felts in Industrial Furnaces and Kilns

Nonwoven felts are crucial to insulating industrial furnaces, kilns, and other high-temperature equipment, particularly in sectors such as metallurgy, ceramics, and glass production. These industries operate at extremely high temperatures, often exceeding 2000°F, where effective insulation is vital to ensure operational efficiency and safety. Nonwoven felts provide the necessary thermal protection, helping to maintain consistent internal temperatures while preventing heat loss.

Furnace Insulation

In industrial furnaces, nonwoven felts are commonly used as lining materials to maintain the internal heat needed for processes like metal forging and glass production. The insulation properties of these felts ensure that the furnaces operate at optimal temperatures, improving energy efficiency and reducing fuel consumption. In addition to thermal insulation, these felts also offer enhanced durability, reducing the wear and tear on furnace linings and extending the lifespan of the equipment.

Kiln Insulation

In kilns, particularly in the ceramics and glass industries, high-temperature nonwoven felts play a vital role in maintaining the precise firing temperatures required for high-quality outputs. By using nonwoven felts as insulation, kilns can prevent significant heat loss, allowing for more efficient energy use and consistent firing conditions. This not only improves the quality of the end product but also reduces operational costs by minimizing energy wastage.

Overall, nonwoven felts are critical in ensuring the durability and efficiency of furnaces and kilns in high-temperature industries.

5. Sealing and Gaskets in High-Temperature Applications

Nonwoven felts are also used in gaskets and seals for industries that operate in high-temperature environments. Seals and gaskets play a crucial role in preventing leaks and maintaining operational integrity, particularly in environments where both heat and pressure are extreme.

Power Generation

In power plants, nonwoven felts are used in gaskets and seals to manage high temperatures in steam turbines and boiler systems. Their ability to resist heat while maintaining a proper seal ensures that these systems operate efficiently without the risk of leaks.

Chemical Processing

Seals made from nonwoven felts are also used in the chemical industry, where they must withstand not only extreme temperatures but also exposure to corrosive chemicals. Their durability and heat resistance make them ideal for protecting critical equipment in these demanding environments.

The ability to maintain thermal integrity and prevent leaks in high-pressure, high-temperature settings makes nonwoven felts an essential material in both power generation and chemical processing.

Conclusion

High-temperature nonwoven felts applications are a cornerstone of industrial applications that demand superior thermal management. Their versatility, combined with their ability to withstand extreme temperatures, makes them indispensable in industries ranging from automotive and aerospace to oil and gas. Furthermore, innovations like the integration of aerogels with nonwoven felts are pushing the boundaries of what’s possible in high-performance insulation, enabling industries to meet the increasing demands of more extreme operating conditions.

As industries continue to evolve and new technologies emerge, the role of nonwoven felts in high-temperature environments will only become more critical. Whether protecting pipelines in harsh environments, insulating spacecraft components, or managing heat in advanced industrial furnaces, nonwoven felts are shaping the future of thermal management solutions.