Why Polyester Felt is the Best Choice for Acoustic Insulation

In design, sound matters. The function of a space is not determined by its aesthetics only but also by the sounds it makes.

“Sound may be invisible or only unconsciously perceived, but that doesn’t make it any less an architectural material than wood, glass, concrete, stone or light.” – Michael Kimmelman.

Sound inextricably becomes attached to function. But because design begins first on paper, it isn’t until we inhabit a room that we determine how to relegate noise.

The growing popularity of decorative acoustic felt panel installation proves that balancing the acoustics of a space does not have to clash with its original design elements. Although it’s true one size does not fit all when it comes to acoustic treatment, polyester felt is proving to be the choice material for acoustic felt panels by the design industry.

What is PET?

Polyethylene terephthalate, or PET, is a thermoplastic polymer resin comprised of recycled transparent plastics. PET is frequently referred to as polyester in textile applications but retains its acronym PET regarding packaging, bottling, etc.

Polyester was first patented in the 1940s by Dupont chemists in Delaware, U.S.A, as a new textile fiber. It wasn’t until the 1970s that new technology made it possible to mold PET into bottles. Today, it is the number one recycled plastic worldwide.

PET is highly flexible in its natural state and therefore easily moldable for its end use depending upon how it is processed. Its applications as the number one recycled plastic range from food packaging and bottling to fabrics to thermoforming in manufacturing and automotive insulation.

The textile industry is a significant end-user of PET, making up about 60% of overall PET consumption.

What is Polyester Felt?

Polyester felt is made of recycled PET plastics, mostly water bottles or other single-use products. The recycled material is compressed and melted down until left with plastic flakes. The plastic bits are then remelted and extruded as fiber. This fiber is then used to produce rolls or sheets of PET textile material, similar in any felting process. It can contain anywhere from 0% to 100% recycled content. Not only is it sustainable, but it is fast becoming the premium choice for sound dampening performance in lieu of other traditional materials, like fiberglass.

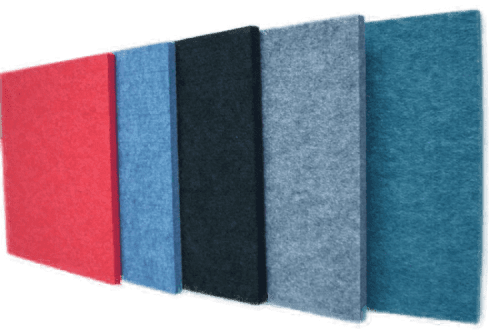

Polyester felt’s lightweight durable nature (combined with an additional lower melting point ) create the ideal properties for acoustic felt panel design. Its capability to be easily cut, variety of color options, and limitless forms are making polyester acoustic panels part of the visual landscape in modern interior design.

Benefits of Using Polyester Felt in Acoustic Insulation

When we design for sound, we are designing for experience. Before, implementing sound insulation into already existing spaces meant the only solution was to hang unattractive hanging baffles and deal with the eyesore.

Now, polyester felt delivers an appealing design in junction with high-functioning performance rates of acoustic insulation.

There is a symphony of reasons the design industry is choosing polyester felt over any other material; acoustically, environmentally, and aesthetically.

Excellent Acoustic Performance

While it is possible, it is challenging to include acoustic design into a space before it has been occupied. In most cases, sound is the last piece an architect will fit into the puzzle. Knowing how a room will be used and where the potential challenges will be for sound issues are essential pieces of the puzzle to negotiate when implementing acoustic solutions. The building layout may not be flexible, but the acoustic solutions can be.

Polyester acoustic felt soaks up ambient noise in a variety of forms. Do you need to mitigate noise in your office conference room? Consider hanging acoustic clouds strategically over spots where noise reflection is at its highest. Are your gym guests experiencing an overload of noise in a large open floor plan? Ceiling baffles would work best here, especially when dealing with higher ceilings.

Using polyester acoustic felt to your best advantage involves finding your key sources of noise and adopting different paneling styles to adapt to the parameters that will help aurally orient your space.

Appealing Function in Design

If, as Kimmerman claims, sound is as vital as wood is for building framing, how far can we take acoustic solutions? Structural possibilities with PET are far-reaching. Its flexible form can be bent, molded, and shaped to any design for an assortment of interior applications, including furniture and lighting fixtures. Designers can exercise creative freedom with a host of different color options and texture choices (dependent on manufacturing methods).

Felt itself is a nuanced fabric that works to your elemental design. You can play it safe and subtle, blending your acoustic felt panels into the background or creating statement pieces that accentuate your already developed design theme. Acoustic insulation can be as simple as under-carpeting or as intricate as 3D ceiling baffles.

Ultimately, polyester felt complements a space without compromising it.

The Sustainable Choice

It is estimated that Americans alone throw away upwards of 35 billion plastic bottles a year. And subsequently, roughly 8 million tons of plastic end up in our oceans. But a major culprit of waste is the textile industry adding billions of pounds of waste to our landfills and depleting energy and water resources.

Reworking the end-use for so many single-use plastic products (and the proposed 95% of all textiles that do have the potential to be recycled), PET is the friendliest raw material in textile applications (among other industries) as well as the healthiest.

Polyester needle punch felt is manufactured without the demand for any chemical additives like glue or resin to bond the fibers. Furthermore, polyester felt does not give off VOCs or odors. This makes it safe for indoor use (able to meet building standards and certifications) while requiring fewer energy resources in the manufacturing process.

The amount of recycled content in PET material can vary from 0% to 100%, depending on the providing manufacturer’s specs and the customer’s desire for a “greener” source. It is not only recyclable at the end of its life but possibly reusable dependent on its modularity.

Designing for the Ears

The acoustic properties of a space have a significant impact on its residents. Managing unwanted noise by integrating acoustic solutions promotes your community’s overall wellness and health, whether it be at home or in your commercial office building.

In the acoustic design process, custom is the standard. Finding the best product for your project starts with making the quality choice of polyester felt. At BIT, we manufacture 100% polyester acoustic panels under our Poly-Sonic line. Each panel has a recycled content of at least 60% PET plastic and is made entirely in the US in our facilities.

Poly-Sonic acoustic felt provides fantastic sound quality that is available in any weight, thickness, or color necessary to meet your specialized products’ demands. We also provide rolled goods that can be molded into any form of acoustic panel solutions or used as a wrapping fabric for other soft-touch surfaces, so the design process is entirely yours.

Acoustics should be a part of your building design, whether you choose to stay traditional or seek out artful installations. Contact us today to learn more about our Poly-Sonic line and how you can begin designing your space for both eyes and ears.

2 Comments

SAm Brickle

GREAT STUFF;;THANKS SAM

Sabahat Chaudhry

Excellent article.

Very Informative

Is this felt suitable for commercial

Applications in buildings,do you any

Flammability test data on polyester felt

Please share.