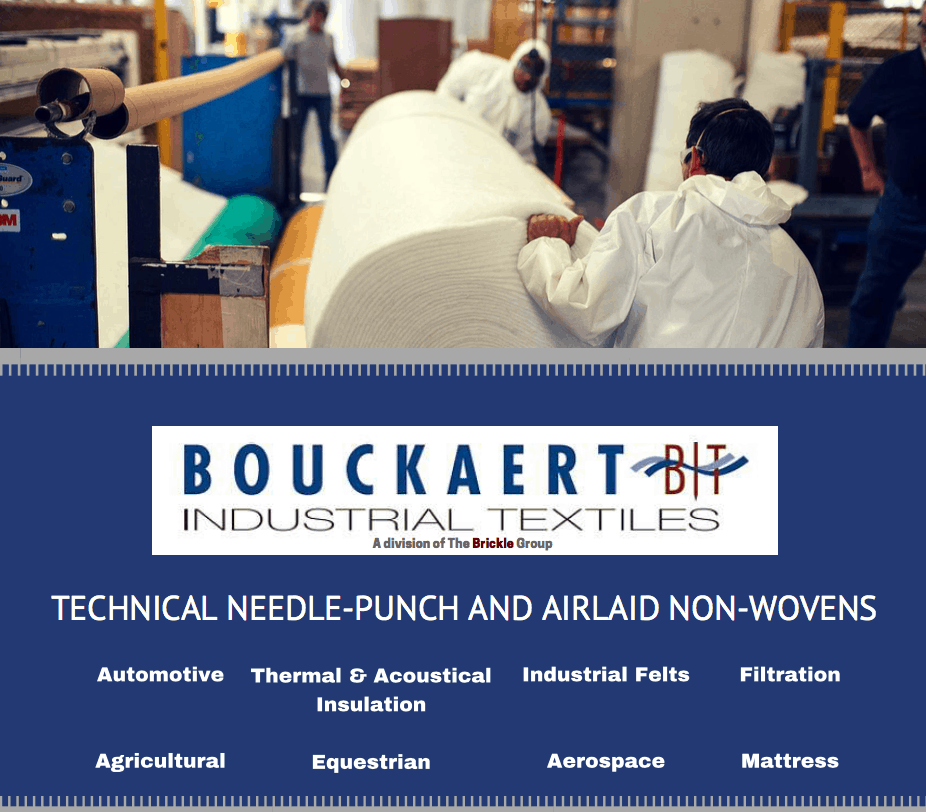

The Only Full Service Felt Manufacturer. From sourcing any fiber, joint development, prototypes, blending, small and high volume roll goods, and cut sheets. Our mission is to create and deliver unique, value-added needle punch and airlaid nonwoven fabrics. Our services include storage, distribution, and just-in-time delivery. Getting new products into the marketplace fast is our commitment to helping our customer grow their business. A partnership with BIT can give you the speed and quality you need!

NATURAL & SYNTHETIC FELT CAPABILITIES

- Full range of needle punch and airlaid felt specifications

- Full range of colors

- Weight: 4oz/sq yard to 500oz/sq yard

- Thickness: .040” to 9”*

- Width: up to 11.15ft (3.4 meters)* (Dependent on production line and method)

- Laminating

- Singeing

- Sheeting

- Prototyping

- PSA Coatings

- Heatsetting

- CNC Cutting

FIBER SPECIALTIES

BIT is capable of sourcing a variety of synthetic and natural fibers including but not limited to:

- Polyester

- Fiberglass

- Polypropylene

- Nylon

- Rayon

- Wool

- Cotton

- Jute

- Sisal

- PLA

MANUFACTURING PROCESSES

Needle Punch

Unlike traditional wet felts, needle punched felt is produced through a technical process using barbed needles. During needle punch felting, the barbed needles puncture the fibers at a rate of 600-2,000 punches per minute. The precise repeated puncturing of the needles entangles and locks the fibers together, creating our industrial felts.

Using different needle combinations, penetration depth, and fiber selections, we can tailor produce our nonwoven needled felts to meet your application needs, including all quality and industry standards (SAE, ASTM, and UL fireproofing requirements).

Needle punched felts can be found anywhere, from simple home craft felt to automotive heat shields. At BIT, our needle punched nonwoven felts are used in many technical industries, including sound insulation, gasketing, and filtering.

Want to talk to one of our sales engineers regarding needle punch felt?

Airlay

The airlaid manufacturing technique originates from the papermaking industry that relied on air as their prime factor. It replaces the traditional use of a carding machine and cross-lapper, instead forming the webs of fibers using air pressure.

The material is accurately measured and blended using a sophisticated pressure control system. The fibers are then fed through two feed rolls and pinned cylinder for a more intense opening. From there, the fibers are condensed to form the desired weight and thickness of the webbed fibers.

This technology results in a uniform product with consistent density while limiting weight variations between lots. The web fibers are then ready to go through our traditional needle punch process to make our standard industrial felts.

The use of air technology is designed to produce matted webs from all types of fibers with the highest quality result.

Want to talk to one of our sales engineers regarding airlay felt?

Just-In-Time Delivery

Just-in-time delivery is a manufacturing process aimed at reducing production times.

Many manufacturers will agree to short-notice orders without having the proper processes in place to allow this to be done safely. Telling workers to “hurry because the customer needs it in two days” is bound to produce errors in the product and increase the risk of accidents.

We have taken the necessary steps to incorporate just-in-time delivery into our everyday procedures. When you need a reliable product fast, Bouckaert Industrial Textiles has the processes in place to get it to you.

We’re Here To Help

Talk to us about your next project.

Tell us what you need and we’ll tell you how we can deliver.